Environmentally Smart Nitrogen (ESN) corn trial at the UF/IFAS West Florida Research and Education Center in Jay, FL. Photo: Mike Mulvaney

Dr. Michael J. Mulvaney, Cropping Systems Specialist, WFREC, Jay, FL

Now is the time to start thinking about nitrogen (N) management strategies for corn production in the Panhandle. This is a follow-up to the March 2016 article: Environmentally Smart Nitrogen (ESN) as a Controlled-release Nitrogen source for Cotton, or ESN for cotton production. Researchers now have data on the use of ESN for corn production in Florida.

ESN is a polymer-coated urea formulated as 44-0-0. The reason it contains 2% less N than urea (which is 46-0-0) is due to the weight of the polymer coating. ESN is commercially available in bulk in some parts of the Panhandle. Many growers blend ESN with urea, commonly as a 50-50 mix, with the idea that some N is immediately available, while the rest will release slowly over time to “spoon feed” the crop.

How slowly does ESN release N?

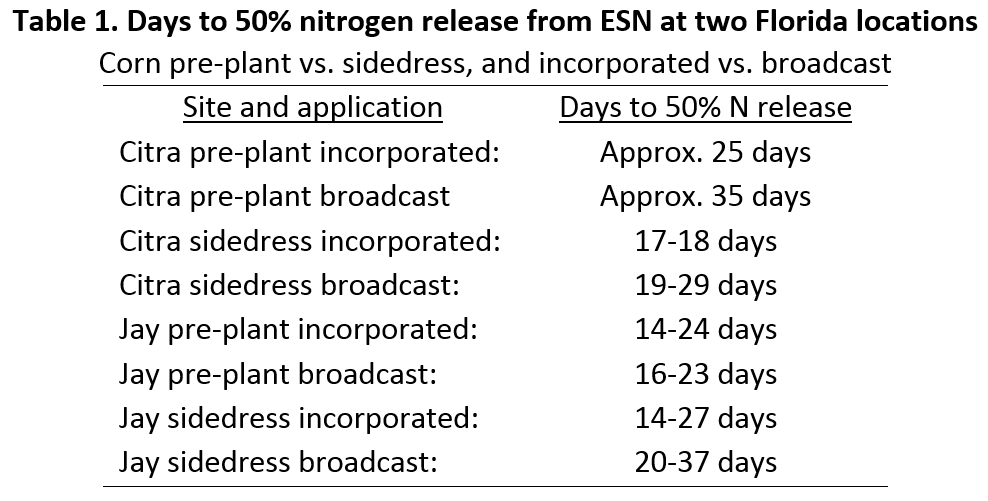

The release of N from ESN is temperature dependent under controlled conditions. That is, the higher the temperature, the faster the release. So, it stands to reason that ESN release should be slower at corn pre-plant as compared to corn sidedress application. Likewise, we should see different N release if we broadcast as compared to incorporating ESN. UF Researchers took this out of the lab, and measured the release rates under field conditions at Jay and Citra, FL during the 2015 and 2016 growing seasons.

The Florida data showed that ESN releases 50% N in approximately 2-5 weeks, with broadcast applications releasing N slower than incorporated ESN.

But does it make a difference in yield?

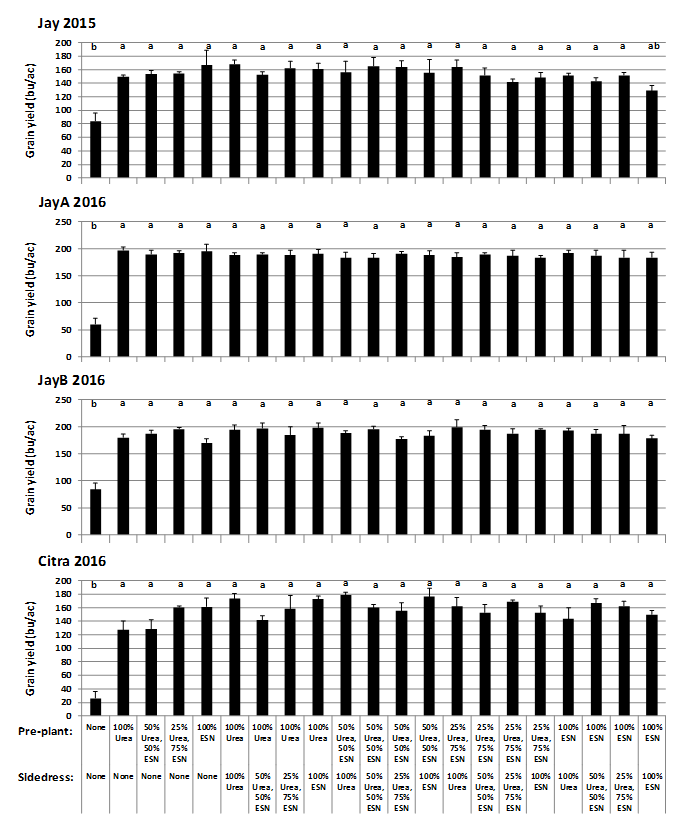

We used different ESN:urea blends at different times (all pre-plant, or 25% N pre-plant with 75% N sidedress) under corn production at two sites across the Panhandle during 2015 and 2016. These corn trials were all fertilized at 183 lbs N/ac (except the control, of course) – the only differences were in how it was applied.

Figure 1. Corn grain yields using various ESN:urea blends, applied either all pre-plant or using a 25% N pre-plant, 75% N sidedress split application. 183 lbs N/ac were applied to all plots except the control.

Yield differences were not statistically significant among any of the application treatments.

Cost

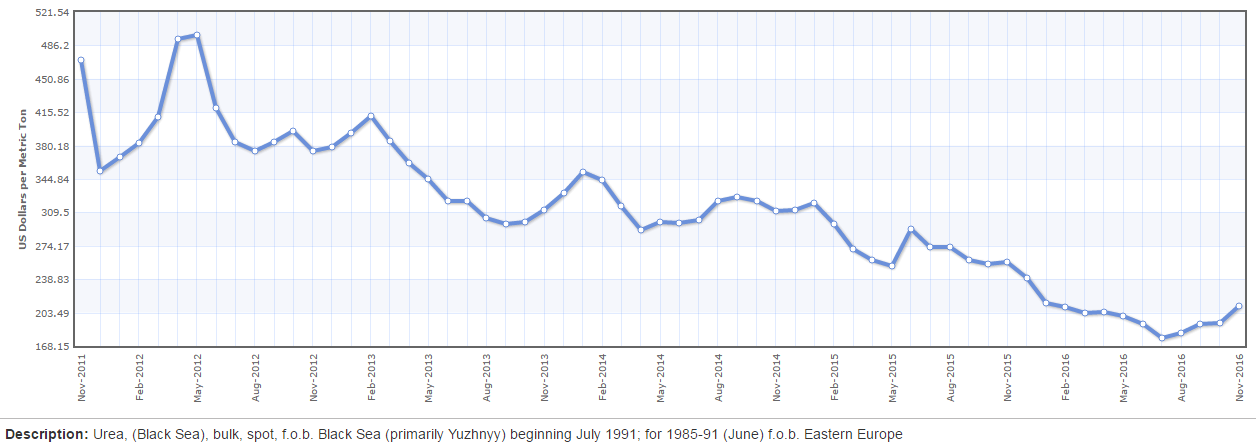

Global urea prices are near 5-year lows, but are about the same price as last year (Figure 2). Locally sourced urea in March of 2016 was selling at $380/ton, and ESN was $600/ton. That’s a 65% increase per unit of N for ESN over urea. March 2015 prices were $560/ton urea and $687/ton ESN, an increase of 28% per unit of N over urea. It is expected that prices in March 2017 will be slightly higher those in March 2016.

Break even cost

If corn prices are $3.60/bushel, and 200 lbs N were applied, you would need a 15 bu/ac yield increase to break even for the additional cost of ESN over urea. If only half of the N was applied as ESN, a 7.5 bu/ac yield increase would be needed to break even.

Summary

During corn production in the Florida Panhandle, 50% of N release can be expected in 2-5 weeks, depending on timing and placement. Although controlled release of N may lead to increased N use efficiency, there was no evidence of significant yield differences among blends, or timing of applications when applied at 183 lbs N/ac at either Jay, FL (a sandy loam) or Citra, FL (sand).

Advantages over urea:

- It may limit the opportunity for N loss through volatilization, which may be useful under certain conditions where urea-N loss can be high (warm, moist, broadcast conditions). Research on N volatilization from ESN is underway through Dr. Cheryl Mackowiak’s program.

- It stores better than urea. It won’t gum up unless prills are broken.

Disadvantages compared to urea:

- It currently costs 65% more per unit of N than urea.

- In a heavy rainfall, broadcast ESN can be pushed into low spots in the immediate area. You can incorporate ESN to help avoid this, particularly if you are on a slope.

- ESN should be handled with reasonable care. Damaged prills are as good as urea but considerably more expensive. When the front-end loader scoops from the bottom of the pile, significant damage can occur to the polymer coating. Also, broadcast applications can damage prills with contact to spreader fins. Incorporation of ESN may damage prills as well, which may explain why incorporated N release was faster than broadcast N release.

- Four Early-Season Lessons from 2020 Peanut Production - April 9, 2021

- Sprayer Calibration Tables – Calibration Made Easy - October 30, 2020

- Stand Issues – Should You Replant Your Peanut Field? - May 15, 2020