by Michael Mulvaney | Apr 9, 2021

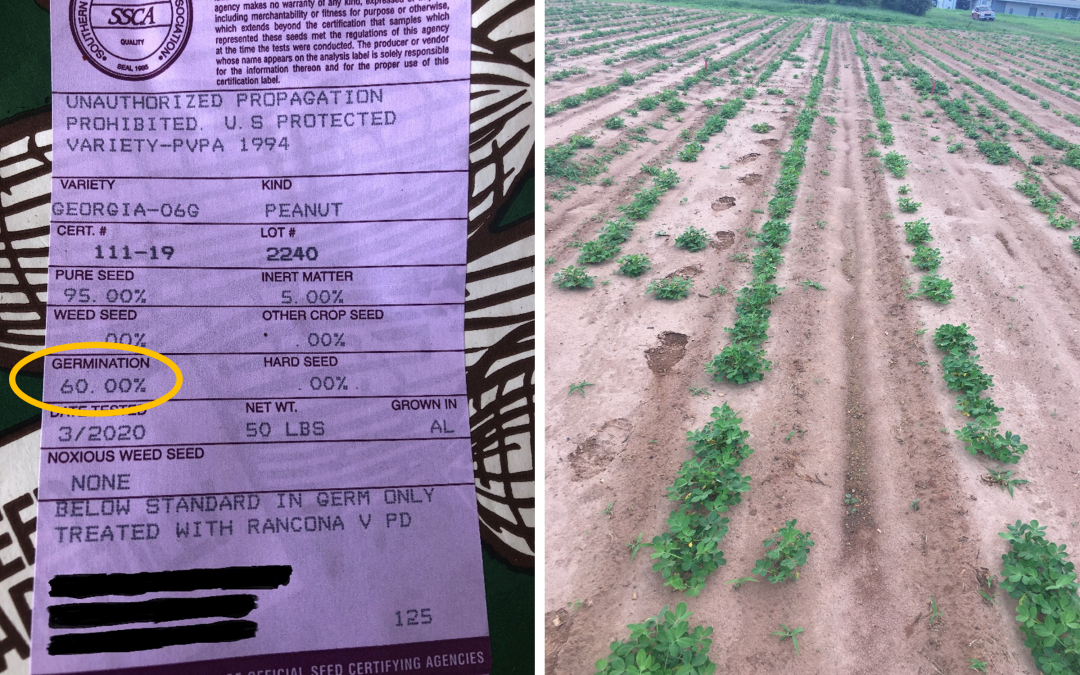

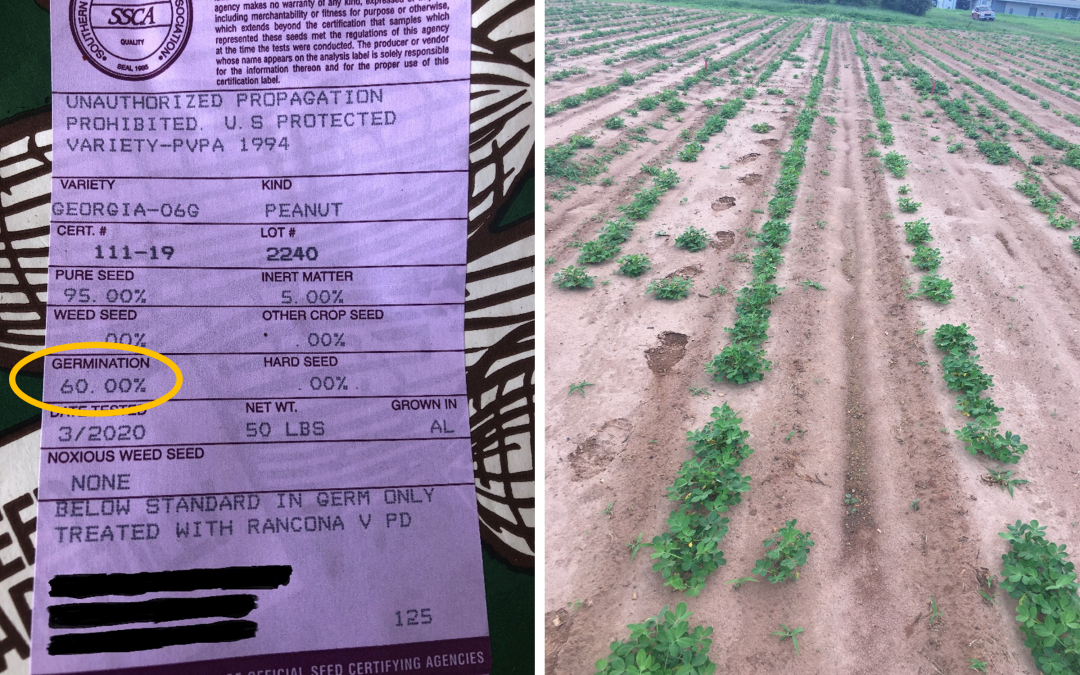

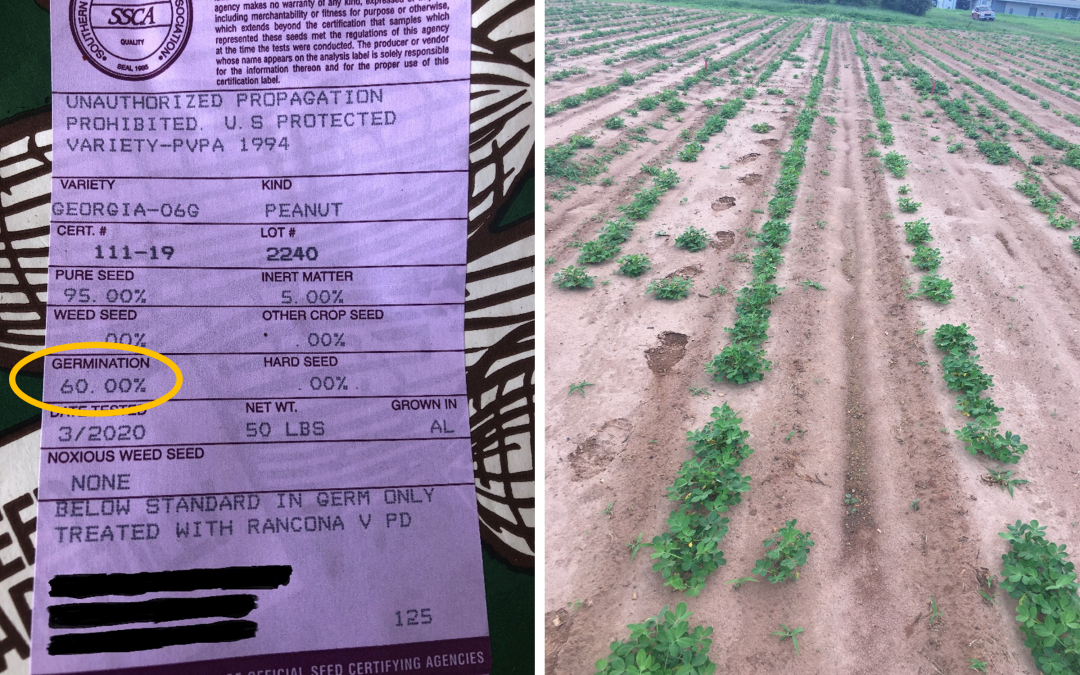

Michael J. Mulvaney, UF/IFAS Cropping Systems Specialist, CCA – Check the germ rate of your seed I was shocked last year to see so many skippy stands, because we didn’t check the germ rate. Many peanut fields had 2 plants/ft! At that rate, you’ve taken your...

by Michael Mulvaney | Oct 30, 2020

Michael J. Mulvaney, Pratap Devkota, Ethan Carter, De Broughton, Mark Mauldin, UF/IFAS Extension State Specialists, Regional, and County Agents The growing season is winding down, and soon harvest will be complete. This is the time of year to recalibrate your...

by Michael Mulvaney | May 15, 2020

Mike Mulvaney, UF/IFAS West Florida Research and Education Center, & Scott Tubbs, UGA Coastal Plain Experiment Station It’s the time of year when producers often face decisions involving replanting peanut. This is always a tough call, there are many factors to...

by Michael Mulvaney | Dec 13, 2019

Irrigation is expensive. And there are a lot of non-irrigated or “dryland” acres across the Panhandle. 2019 was characterized by persistent drought stress for much of the season (see below). So in a dry year like 2019, what are you supposed to do to manage...

by Michael Mulvaney | Jun 21, 2019

Arun Jani and Mike Mulvaney, West Florida Research and Education Center Climatic conditions in North Florida can pose serious challenges to growers aiming to maximize returns on investments made in nitrogen (N) fertilizer. Most plant available N in local soils is in...