by Doug Mayo | Jul 11, 2025

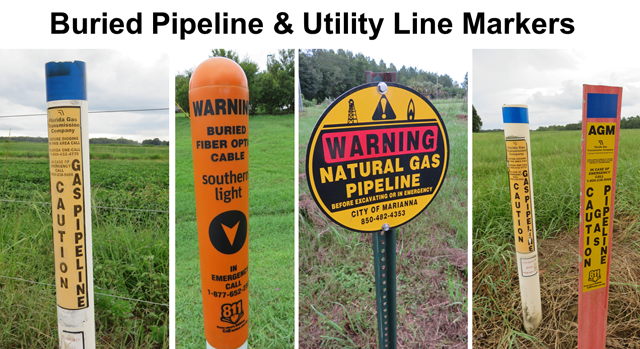

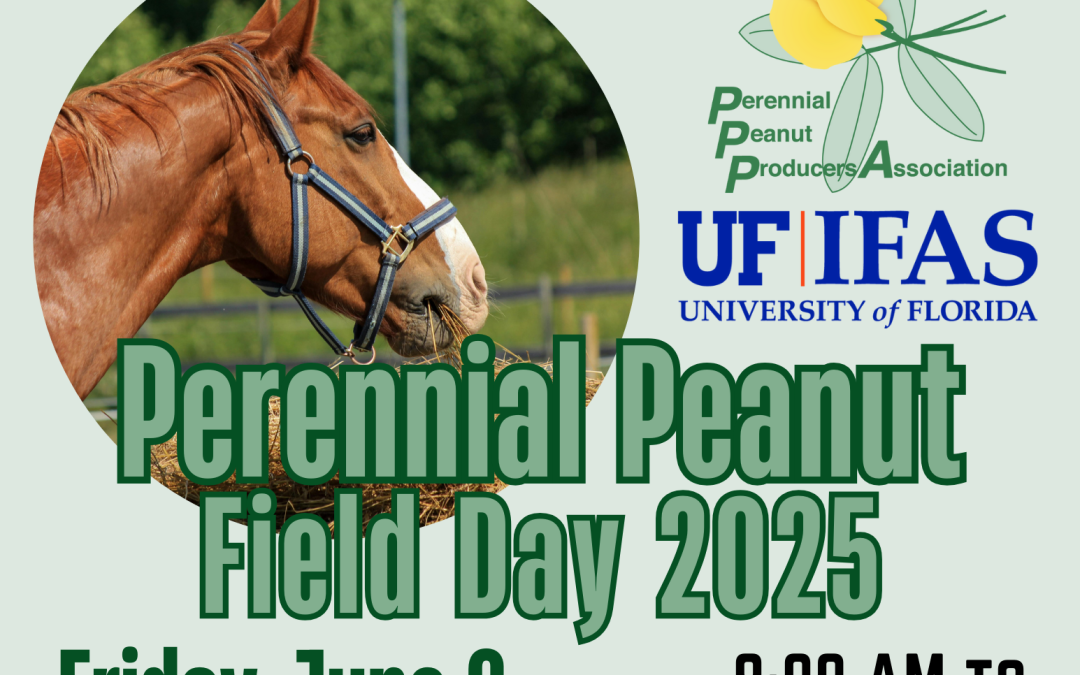

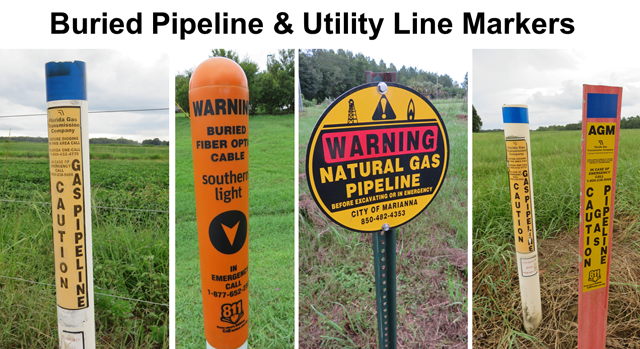

At the recent National Association of County Agricultural Agents Conference, I attended a training where a video was shared that really got my attention, called Three Seconds Later. The video shared the tragic story of a father and son that lost their lives when the...

by Doug Mayo | Jun 6, 2025

This week’s featured video was published by the Panhandle Ag Extension Team. Bill Conrad, Jackson County, was selected to present at the Perennial Peanut Producer’s Association Field Day, that was held on Friday, June 6, in Marianna. Part of his...

by Doug Mayo | Apr 25, 2025

If you are a perennial peanut producer, or are interested in becoming one, you are invited to attend the annual Perennial Peanut Field Day. In 2025, the Field Day will be held in Marianna, Florida, on Friday, June 6, from 9:00 AM to 2:00 PM Central time (10-3...

by Robbie Jones | Apr 11, 2025

To say the least, we had an eventful winter across the Panhandle. Who would have thought in their lifetime we would see more snow than many northern states, 5 inches of snow in many places across the Panhandle, and snow on the Gulf Beaches! As warm weather is upon us...

by Doug Mayo | Apr 4, 2025

This week’s featured video was published by CBS Saturday Morning to share the story of the International Harvester Scout and the comeback planned for 2027. The last Scout came off the assembly-line in 1980. Since it was no longer in production, the Scout...

by Doug Mayo | Mar 14, 2025

This week’s featured video was published by NCBA’s Cattlemen to Cattleman to share the highlights of a pilot project in Kansas that includes Vence virtual fencing. USDA’s Natural Resources and Conservation Service (NRCS) has partnered with Mushrush...