by Cheryl Mackowiak | Jul 18, 2025

Ramdeo “Andy” Seepaul, Ethan Carter, Ian Small, and Cheryl Mackowiak, UF/IFAS North Florida Research and Education Center Cotton production in Florida’s Panhandle presents a unique set of challenges: light, sandy soils, variable rainfall, and diverse field...

by Ethan Carter | Jun 20, 2025

Ethan Carter, Regional Crop IPM Extension Agent; Hardeep Singh, Cropping Systems Specialist; Michael Dukes, Director of UF/IFAS Center for Land Use Efficiency; and Lakesh Sharma, State Ag BMP Coordinator In recent years, the University of Florida has worked...

by Muhammad Shahid | May 22, 2025

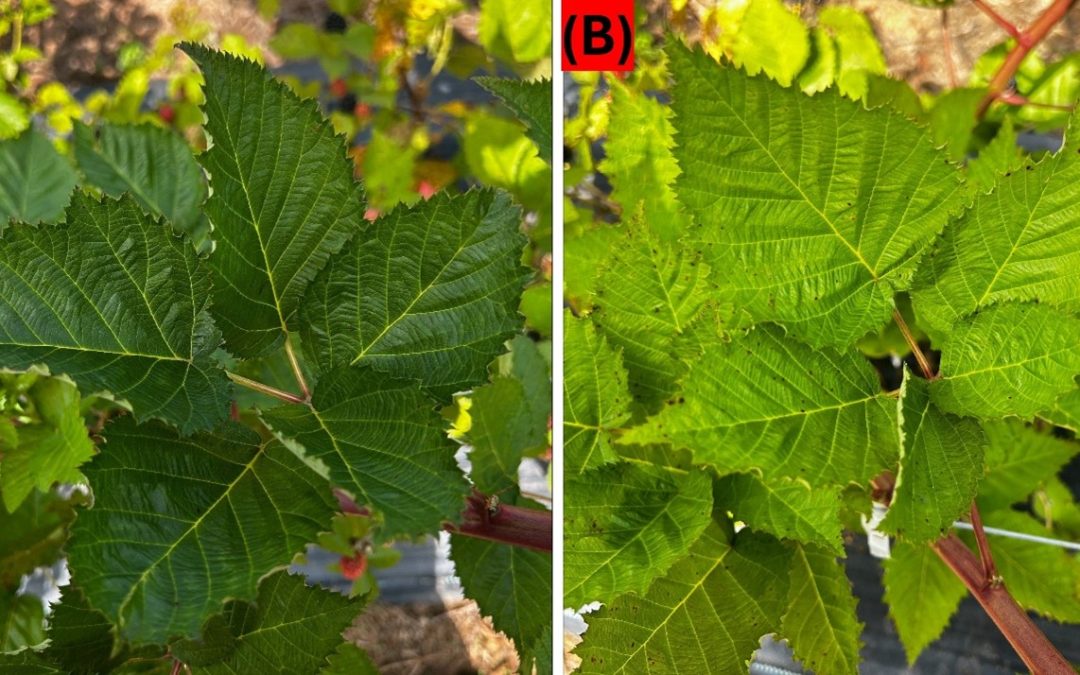

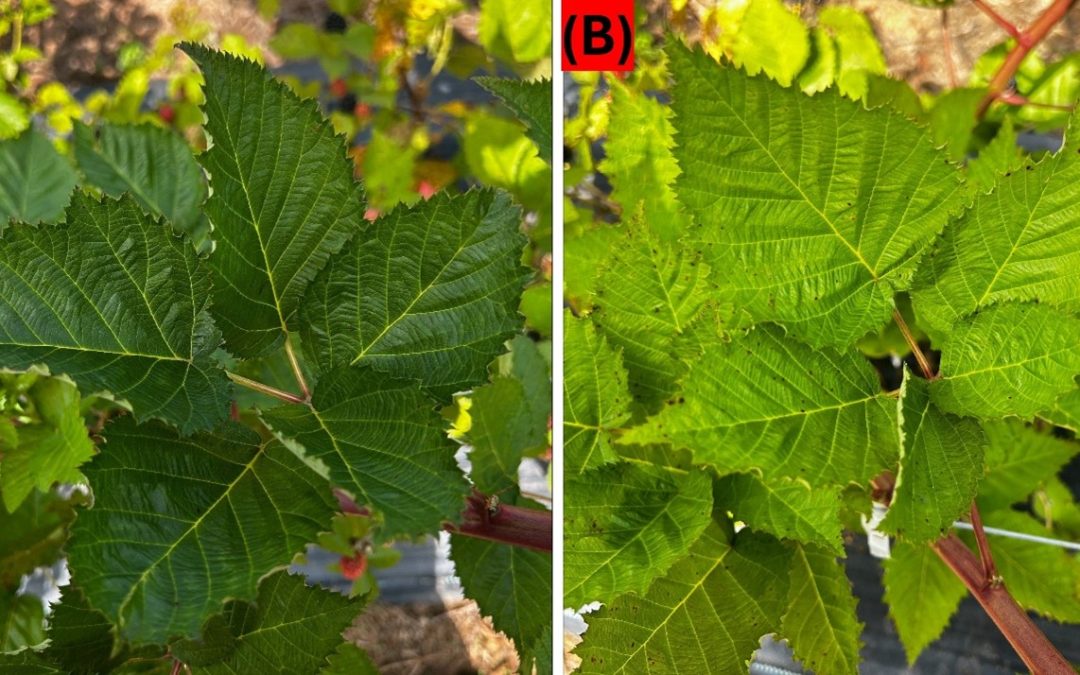

Muhammad Shahid, Carlos Eduardo Aucique-Perez, and Shahid Iqbal, Horticultural Science Department, North Florida Research and Education Center, UF/IFAS, Quincy, FL Nitrogen (N) plays a vital role in the growth and development of blackberry plants by supporting...

by Abbey Smith | Apr 4, 2025

Best Management Practices (BMPs) for water quality enhancement and conservation are essential to the long-term sustainability of agriculture and natural resources in Northwest Florida. BMPs allow producers to gain knowledge and understand how to decrease their impact...

by Matt Lollar | Mar 21, 2025

Manure from livestock has been used by farmers and gardeners since the beginning of farming, with evidence of the benefits of manure are documented dating back nearly 8,000 years. Manure can help improve soil, but there are a couple common misconceptions about its...

by Ben Hoffner | Mar 14, 2025

Effective soil fertility management is an essential practice for livestock producers in Florida’s Panhandle who want to efficiently enhance forage production. Regular soil testing provides valuable insights into the amount of plant available nutrients in the...