Jay Ferrell, & Ramon Leon, UF/IFAS Weed Speciaslits R. and Ethan Carter, Regional Crop IPM Agent

After many years in development, dicamba use in tolerant cotton varieties will likely be fully approved for the 2017 growing season. As everyone is well aware, there is great concern that dicamba drift can result in significant losses if sensitive crops are growing nearby. This concern is well founded since many crops (such as soybean, snap bean, and peanut) have proven highly sensitive to extremely low doses of dicamba. It will be very important that all precautions be followed if dicamba is to be used this season. Some important considerations are herbicide selection, use of ammonium sulfate, nozzle selection, and boom height.

Herbicide Selection:

Dicamba has been available and widely used by corn, small grain, and pasture managers for over 50 years. As such, there are many different brands of dicamba in the marketplace. However, it is essential that only products approved for use in dicamba tolerant crops be used. The approved herbicides (Xtendimax from Monsanto and Engenia from BASF) must be used because they have been engineered to have very low volatility. Volatility is the potential of the herbicide to turn into a gas after the application, while maintaining full herbicidal potency. Using a “Banvel-type herbicide” is not allowed as the volatility of this formulation is simply too high for a safe application.

Additionally, never add ammonium sulfate with Xtendimax or Engenia. Adding ammonium sulfate (which is the principle component of many water conditioners sold at the retail level) creates unique chemical forces in the spray water that converts low volatility dicamba products into a form that is equal or more volatile than Banvel. So adding ammonium sulfate removes all the safety that has been engineered into the Xtendimax or Engenia formulations.

Nozzle Selection:

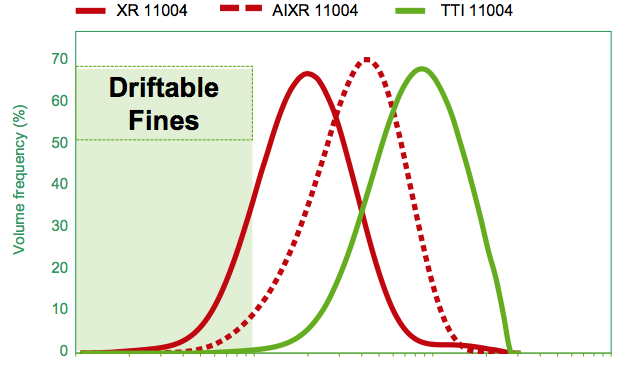

Drift reducing nozzles have been available in various forms for several years. However, the dicamba labels will explicitly require a TTI (Turbo TeeJet Induction) nozzle. Why is this important? All nozzles create a range of droplet sizes from large to small. But the issue for each nozzle is how many small droplets are formed and are they small enough to drift. After years of research, it has been observed that all nozzles produce some level of “driftable fines” (super-small droplets that will drift), except the TTI nozzle (Figure 1). Additionally, these nozzles should not be operated at a pressure greater than 63 PSI. Higher pressures mean smaller droplets, so keeping the pressure below this threshold ensures that only the largest droplets are produced. So using a drift reducing nozzle is not sufficient. It is essential that a TTI nozzle be used at the proper pressure. In the future, new nozzles will be added to this list as technology evolves, so it will be important to stay in touch with this information. But in the meantime, to ensure this transition to TTI nozzles, some companies are providing TTI nozzles free of charge with the purchase of their herbicide. Please contact your local sales representatives for more information.

Figure 1. Spray droplet distribution from three commonly used nozzles. *Note the TTI nozzle produces almost no driftable fines compared to the other two. BASF Corp., used by permission.

Boom Height:

Height of the spray boom above the crop is essential to reducing drift. The shorter the distance the droplet has to travel, the less likely it is to move off site. For this reason, a maximum of 24 inches above the soil surface or the crop canopy is the required boom height. Exceeding this height dramatically increases drift potential.

Dicamba has the potential to improve weed control in our most troublesome fields when applied appropriately. However, it also has a risk of devastating neighboring crops if used incorrectly. Therefore, it is essential that all producers planning to use this technology also plan to follow all the label precautions. If we all commit to these criteria, I believe we can have a year of good weed control with minimal issues of off-target injury.

- The How and Why of Preemergence Herbicide Incorporation for Row Crops - April 28, 2017

- Using Dicamba on Dicamba-Tolerant Crops - March 3, 2017

- Managing Dicamba Drift when using New Dicamba Resistant Cotton Varieties - January 27, 2017