Many fungicide products are examined each year for their efficacy. This is an example of one trial conducted at the NFREC in Marianna Florida.

Nicholas Dufault, UF/IFAS Crop Pathologist, and Patrick Troy, UF/IFAS Row Crop Regional Agent

As the 2018 peanut production season approaches, it is time for producers to start considering their fungicide programs. Chlorothalonil has been a staple fungicide in many peanut management programs, but shortages of this product are expected in 2018 as well as possible cost increases. Chlorothalonil is a critical broad-spectrum fungicide that has activity against early and late leaf spot as well as peanut rust. It is also an important tool for fungicide resistance management that can be mixed with high risk fungicide products (e.g. tebuconazole, azoxystrobin, etc.) to improve disease control. With short supply this year, growers may need to consider ways to stretch chlorothalonil use with alternative products that offer disease control at a reasonable price.

Tank Mix Options for Lower Rates

Tank mixing chlorothalonil with other fungicide products is one way to reduce the application rate from 1.5 pints/A or 1.4 lbs./A to 1.0 pint or 0.9 lbs. per acre for the flowable and dry flowable formulations, respectively. Some mixing products are:

- FRAC group 3 fungicides: tebuconazole (multiple generics, 7.2 fl oz/A), cyproconazole (Alto®; 5.5 fl oz/A), flutriafol (Topguard®; 7 to 14 fl oz/A) and tetraconazole (Eminent®, 6 to 13 fl oz/A).

- FRAC group 11 fungicides: azoxystrobin (18.5 fl oz/A), pyraclostrobin (Headline®, see label for rates) and fluoxastrobin (Evito®, 5.7 fl oz/A).

- Some Premixed compounds (Custodia®, Absolute®, Elatus®, etc) that can also be mixed with chlorothalonil.

These are just a few examples of fungicides that can be mixed with chlorothalonil. A more complete list can be found in the 2017 Peanut Update and other mixing scenarios in the 2015 Auburn Extension guide (PP-765). Besides mixing with other products, it is also possible to use a reduced rate of chlorothalonil on its own. This should only be considered early in the season when disease pressure is low or absent, and/or in areas that have had minimal rainfall.

Alternative Products

A few products that can substituted for chlorothalonil are:

- dodine (Elast®, 15 fl oz/A)

- mancozeb (multiple generics, 2.0 lb/A)

- thiophanate-methyl (Topsin®-M, 5 to 10 fl oz/A).

Both dodine and mancozeb are protectant products similar to chlorothalonil, and are generally recommended as mixing partners with products like tebuconazole and Topsin®-M. However, 2017 data from Auburn University showed that both of these products alone reduced late leaf spot defoliation, and saved yield when compared to the untreated control. Even so, yield savings tended to be greater when these products were mixed with other fungicides. When using thiophanate-methyl, resistance is a concern. So, no more than 2 applications of this fungicide are recommended, and consecutive applications need to be avoided.

The fungicide products Provost® Opti, Elatus®, Fontelis® and Priaxor® are chlorothalonil alternatives that can be applied alone and tend to provide soil borne disease control as well. It is important to consider cost and the disease of interest when considering these or any other fungicides.

Reducing Applications

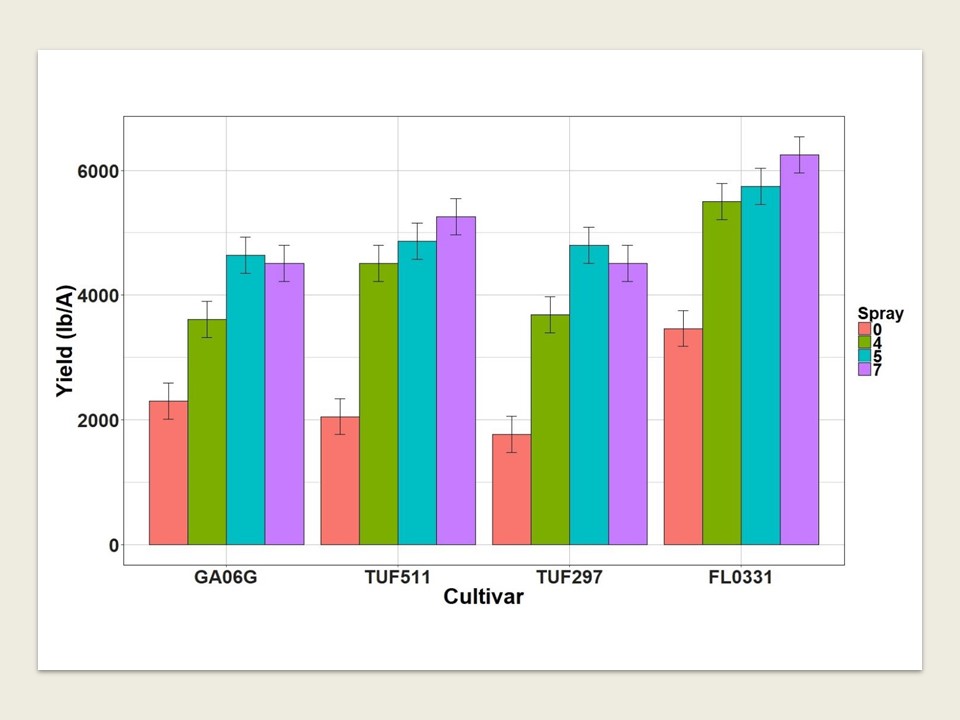

If the goal is to possibly eliminate one or two chlorothalonil sprays, then it is recommended that special attention be given to the peanut variety’s resistance traits, preseason disease risk and the current or predicted frequency of rainfall. Research at the University of Florida has indicated that in years when total defoliation is less than 50% at harvest, similar yields can be achieved with spray programs consisting of 5 and 7 sprays (Fig. 1 below). However, both environment and variety were important factors driving these results. Thus, it is critical that as much information as possible about disease risk and presence be collected before making spray reduction decisions. Producers are advised to watch 10-day rain forecasts and appropriately shorten spray intervals in especially wet weather or increase them in dry weather.

Fig. 1. Yield results from the 2016 spray input by variety trial conducted at the Plant Science and Education Unit in Citra, FL. The cultivars in the trial were Georgia-06G (GA06G), TUFRunner 511 (TUF511), TUFRunner 297 (TUF297) and FloRun 0331 (FL0331). Spray application numbers varied from 0 (no sprays) to 4, 5 and 7 sprays within the season. Each spray program is represented by a different color according to the legend on the right. Fungicides used in the applications programs were chlorothalonil, tebuconazole and azoxystrobin. Chlorothalonil was applied in every spray of each program either by itself or as a mixture. All spray programs had one application of azoxystrobin at 90 days after planting (DAP). The 4 and 5 spray programs had two applications of tebuconazole at 60 and 115 DAP. The 7 spray program had three tebuconazole applications at 60, 75 and 105 DAP. Error bars represent the standard error of the mean.

There are many fungicide options available for peanut disease control, and it is not possible to go over all the combinations here. Producers are encouraged to work with University of Florida extension personnel and chemical dealers to develop an appropriate disease management strategy for their field and rotate FRAC chemistries. They are also encouraged to consult the 2018 version of Peanut Rx which will be available at the UGA peanut website, as a smart-phone app and through various program publications from a number of chemical companies. Developing disease management strategies can be difficult. However, while some fungicides can vary in their disease control performance, they all continue to provide quality tools for disease management.

Further information can be found at:

On-Farm Evaluation of Fungicide Programs for Peanut Disease Control

Evaluation of Foliar Fungicides for Disease Control in Peanut

Management and Cultural Practices for Peanuts

- Southern Rust Confirmed in the Florida Panhandle – June 2025 - June 6, 2025

- Stay Ahead of Disease with the Spore Report: A New Tool to Assist with Potato and Watermelon Management - April 11, 2025

- 2024 End-of-Season Florida Peanut Disease Notes - October 11, 2024