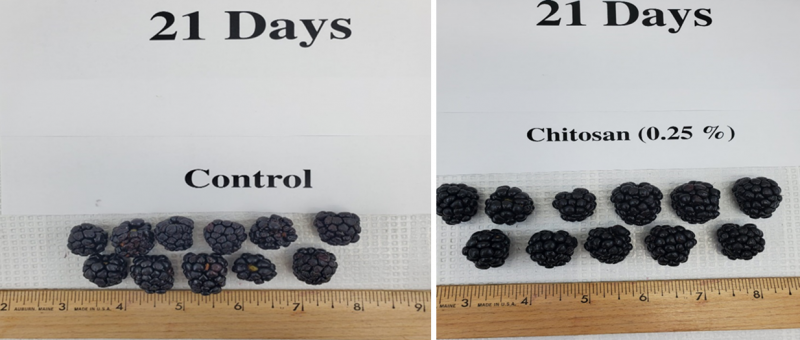

Figure 1: Chitosan treated fruit after 21 days of cold storage cultivar (Osage) Credit: Muneer Rehman, UF/IFAS

Muhammad Shahid and Muneer Rehman, UF/IFAS North Florida Research and Education Center

Chitosan is an edible coating material used to extend the shelf life of perishable commodities. It is a natural polysaccharide derived from chitin, a main component found in the exoskeleton of crustaceans such as crabs, shrimp, and insects. Chitosan is nontoxic, biocompatible, and biodegradable, and it has antimicrobial activity against a wide range of bacteria and fungi. The incorporation of chitosan into the packaging material or direct application on the food surface helps to inhibit the spoilage caused by microorganisms. Moreover, chitosan has good moisture barrier properties, as moisture accelerates the deterioration of many food products, leading to microbial growth, enzymatic reactions, and other forms of spoilage. Chitosan-based coatings or films act as a protective barrier against moisture, helping to maintain the quality of the food and prolong its shelf life. Chitosan can be applied as an edible coating directly onto the surface of fruit, vegetables, and other perishable products. This coating provides a protective layer, retarding moisture loss, reducing microbial contamination, and maintaining product quality for a longer period. Previously, chitosan applications were noticed to be efficient in reducing post-harvest decay in strawberries, avocado, papaya, mango, and blueberries.

Blackberry (Rubs spp) belongs to the family Rosaceae and is known as super food due to its high nutritional value containing vitamin C, antioxidants, and phenolic compounds. Blackberry is a deciduous crop that grows best in temperate climates. Several blackberry species are native to Florida, and varieties that performed well in North and North Central Florida include Osage, Chickasaw, Apache, Arapaho, Choctaw, Ouachita, and Kiowa. Recently, significant acreage of different blackberry varieties have been planted in North Florida, due to the favorable climatic conditions. However, the highly perishable nature of the fruit poses substantial implications for fresh market and storage.

Cold storage is a widespread approach used to extend the shelf life of fruit, including blackberries. Cold storage helps to slow down various biochemical and physiological processes, involving respiration and microbial growth, which are responsible for the deterioration of fruit quality. Blackberry fruit is fragile, highly perishable, and must be handled with care. Moreover, blackberry fruit is typically stored no more than 2-3 days at cold temperatures 34-36° F (1 to 2◦C). In addition, blackberries are also susceptible to water loss, fruit softening, fungal rot, mechanical injuries, leakage, and red drupelet reversion.

Fig 2: Effect of chitosan on the shelf life of blackberry fruit (Osage) stored at 1◦C for 7 and 21 days. Credit: Muneer Rehman, UF/IFAS

–

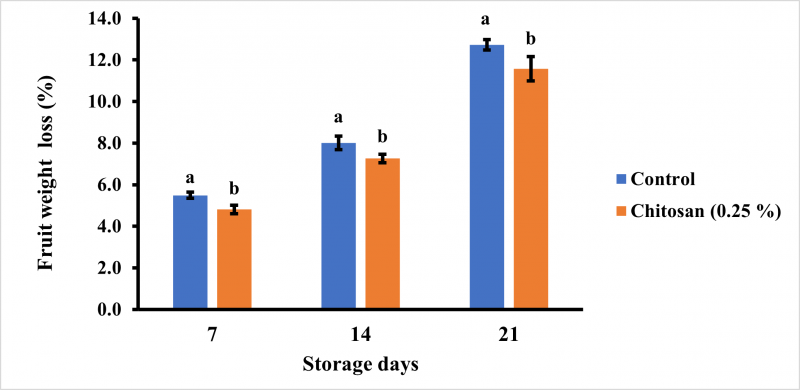

Chitosan emulsion used as a pre-harvest spray application significantly reduced fruit weight loss (%) in blackberry fruit stored at 1◦C for 7, 14, and 21 days. Fruit weight loss during cold storage is a critical factor in deciding the blackberry quality. Furthermore, weight loss (%) has correlation with fruit firmness, leakage, red drupelet reversion, and marketing index.

Figure 3: Pre-harvest spray application of chitosan emulsion reduced fruit weight loss (%) during the fruit stored at 1◦C for 7, 14 and 21-days. Credit: Muneer Rehman, UF/IFAS

–

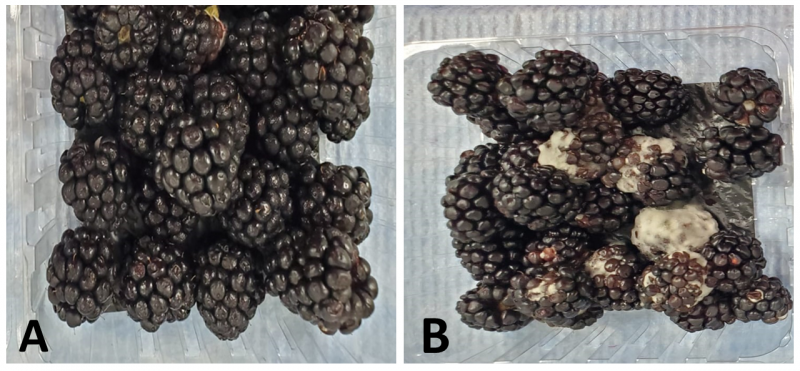

Blackberries stored in cold storage showed signs of mycelium growth, if conditions were favorable for fungal development. The most common contaminants during the postharvest handling and storage of blackberry fruit are fungi and molds. Direct application of chitosan on the fruit surface reduced the mycelium growth.

Figure 4: Chitosan treated fruit (A) with no or little sign of mold, while (B) is control. Credit: Muneer Rehman, UF/IFAS

–

Research trials on the effect of different concentrations of chitosan emulsion alone and in combination with growth bio-stimulants as pre-harvest and post-harvest applications are ongoing at the Fruit Physiology Lab, at the North Florida Research and Education Center, in Quincy, Florida.

- Boosting Citrus Cold Hardiness with Seaweed Extract Biostimulants - November 21, 2025

- Optimizing Nitrogen Use for Sustainable Blackberry Production in the Florida Panhandle - May 22, 2025

- Citrus Sunburn: A Physiological Disorder - May 17, 2024