Hay Feeding Waste Demonstration at the North Florida Research and Education Center’s 2024 Beef & Forage Field Day. Credit: David Thomas, Beef Unit manager for Demo, and the photo Doug Mayo, UF/IFAS

Source: Proceedings of the 2024 NFREC Beef & Forage Field Day, Doug Mayo, UF/IFAS Extension Jackson County, and David Thomas, NFREC Beef Unit Manager

Most ranches in the Southeast have the goal of producing or buying 4-6 round bales of hay or equivalent baleage (50-60% moisture) per cow/calf pair annually. Certainly, winter grazing can significantly reduce your reliance on hay or baleage, but most operations do not have enough acres of cool-season forage to rely solely on grazing from first frost to spring perennial pasture growth (mid-November through mid-April). Hay is typically the backbone forage of the winter supplementation program for cow-calf operations in this region. Since hay is such an import part of cow-calf production, it is also vitally important to minimize waste as much as possible.

According to the October 31, 2024, Alabama Direct Hay Report, Round Bale hay sold for an average of $134/ton depending on the size and quality of the hay. While hay is cheaper per ton than most every other supplemental feed option, ranchers will feed more tons of hay or baleage than any other feed supplement through the winter. A 1,200-pound cow that consumes ~2% of her body weight will need 24 pounds of dry matter (DM) each day, so you can plan on providing 1.8 tons of DM through the 150-day cool-season per breeding cow in your herd. Depending on the support from winter grazing, you will need 1-2 tons of hay (88% DM) per cow. The part that is often not tracked or calculated is the amount of waste that is an inevitably part of hay storage, transportation, and feeding. You must account for waste to determine the total number of bales produced or purchased to feed your herd through the winter and during short-term drought periods.

–

Storage Waste

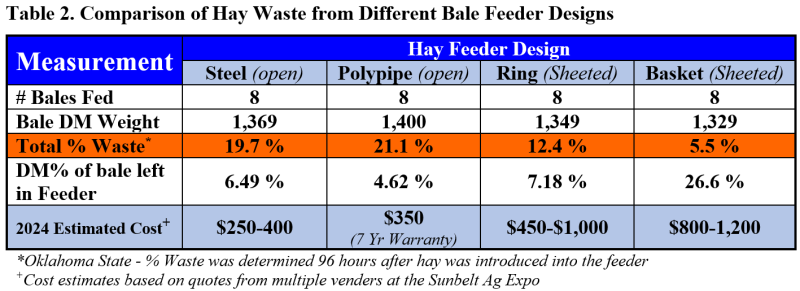

How hay is stored greatly affects both the dry matter weight and forage quality. Based on research from Eastern Oklahoma, where they typically receive greater than 40” of annual rainfall, Raymond Huhnke, Extension Agricultural Engineer, developed the data in Table 1 below that compares dry matter losses based on how hay was stored on a short-term and long-term basis. These losses would be even greater in climates with 55” of annual rainfall, such as the Florida Panhandle.

Source: Oklahoma State – Round Bale Hay Storage – BAE-1716

–

Notice that the simplest way to reduce storage losses came from elevating hay off of the ground. The rot on the bottom of the bale, that does not dry out, is generally worse than the weathered outer edges of the bale that get rained on. Of course, the best method to prevent storage waste is to store it under a roof (5%) or in an enclosed barn (<2%). A tarp also reduced waste, especially if the area was elevated to reduce ground moisture to prevent bottom rot.

Forage-Livestock Quotes and Concepts has a great quote when it comes to hay storage waste, “Some folks pay for a barn they never build.” The author’s point was that dry matter losses, and leached nutrients can exceed 30% from storing hay unprotected from weather. Plus, weathered hay is less palatable, so it may also reduce intake by the animals being fed. So instead of consuming the expected 24 pounds of dry matter per day, cows might consume less than what is needed to meet nutrient demands. The point of the quote is that while hay barns are expensive, hay waste from outside storage will be more expensive over an extended period of time. So, you really can pay for a hay barn over time, if you can reduce storage waste significantly.

–

Feeding Waste

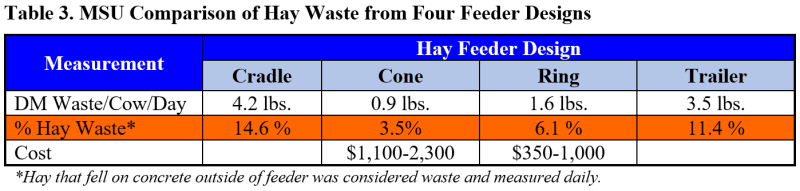

Another key part of hay waste management is the equipment used to feed hay to the herd. Another quote from Forage-Livestock Quotes and Concepts refers to hay feeding losses, “Wasted Hay Means Wasted Money!” You can do everything right from managing a timely harvest, keeping hay dry and storing it well but still have waste based on the equipment used to feed the animals. Researchers from Oklahoma State (Sexton et.al. 2021) compared hay waste using the four hay bale feeders pictured below. There were 56 Angus X crossbred cows in the second trimester of pregnancy that were fed eight round bales, and the waste was measured 96 hours after the hay was introduced using one of the four feeders.

Comparison of four specific hay bale feeders in 2021 Oklahoma State Study. Credit: Hay Feeder Design Effect on Hay Waste – ANSI-9413

–

–

I think the most important things that can be gleaned from this study were that the sheeted bottom skirts made a significant reduction in waste from hay feeding. The basket feeder provided an added benefit of holding the bale away from the edge of the feeder to reduce hay falling out on the ground. The basket feeders that I got price quotes on at the Sunbelt Ag Expo were significantly more expensive, but if hay waste can be reduced from 20% with a typical ring feeder to 6% (as in this study) with the basket feeder, this extra expense could generate significant savings, if the feeder lasts for several seasons.

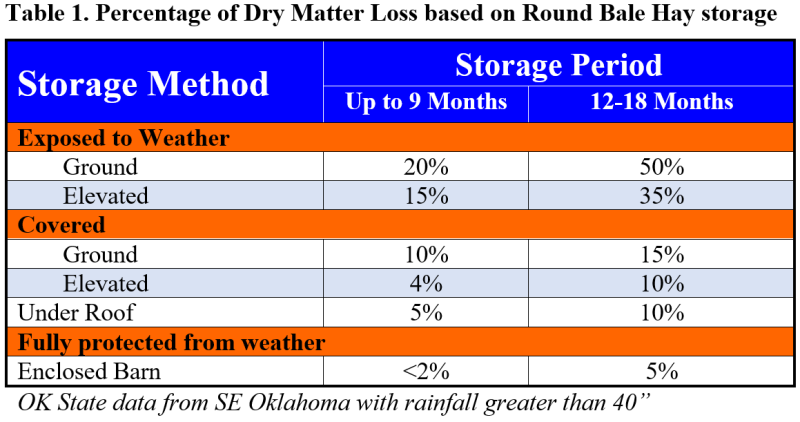

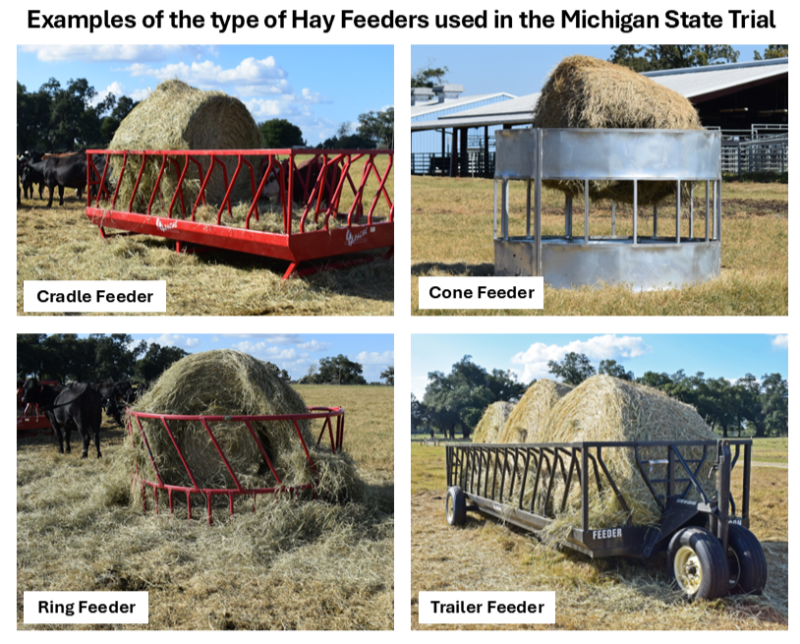

Another research trail was conducted at Michigan State University that compared waste from four different types of hay feeders. There were 160 cows divided into eight pens with four different designs of round bale hay feeders. After one week the cows were moved to a new type of feeder for a second week of comparisons. Each of the feeders was placed on a concrete pad. Hay that fell outside the feeders was considered waste and was collected and weighed daily. The photo below show the general types of equipment evaluated in the study, but are not the specific equipment that was used, as no photos were provided with the trial summary like they did in the Oklahoma trial summary.

Examples of the types of hay feeders compared in the Michigan State Trial. Note: These are not photos of the specific equipment tested in the study. Credit: Doug Mayo, UF/IFAS

–

–

The main takeaway from this study was that the cone feeder, that suspends hay above the feeding area, reduced hay waste considerably more than the other feeders evaluated. In this study, the hay cradles and trailers had even higher levels of waste than the typical ring feeders. It really depends on how the equipment is built, because the waste comes from the ease of access to the hay. You can’t compare trial results equally from two different studies, because the methods used and the timing of measurement of waste were very different. The cone feeder in the pictures above came from new equipment recently purchased for use at the North Florida Research and Education Center (NFREC) Beef Unit, so it will be interesting to learn about the level hay waste these feeders actually provide over time with locally grown hay and climate.

–

Summary

These are just a few examples of the types of trials that have been conducted at multiple universities that show that there are different management options available to reduce hay waste. Every data set from individual trials cannot be equally compared, because of the varying research methods used, but I think they demonstrate key takeaway points for management options available that can reduce hay waste.

- Hay storage waste should be minimized as much as possible. Protect hay dry matter (tons to be fed) and nutrient content (hay quality) the best ways you can. Keep the bottoms of the bales dry with drainage or even better elevation, or a barrier from the ground to prevent dry matter waste. Protect bales from direct rainfall either with a cover, wrap, or barn roof to protect feed quality. If you are going to store hay outside, ensure bales are packed tightly with net-wrap, or even better with the new B-wrap, as opposed to string, and stack in well drained areas that allow the bottoms to dry out after heavy rain events.

– - Hay feeding waste can be considerable. Hay that falls on the ground and gets stomped on is likely not going to be eaten. The most efficient feeders are cone or basket feeders with solid sides to keep hay in the feeder, followed by ring feeders with solid sides. The most efficient feeders are typically much heavier to move and more expensive than the basic ring type feeders, so take feeder cost and weight into account before making purchase decisions. Any type of hay feeder is more efficient than simply feeding hay on the ground with free access by the herd. If you feed 5 850# round bales/per cow with a basic ring (no skirt), you are wasting ~20% or 850# (1 bale) per cow, worth $57. Use a ring with a skirt around the bottom and your waste is ~12%, then 510 pounds, or $34/cow. Use a basket @ ~5.5% waste = 234# or $16/cow, or a cone @ ~3.5% = 149# or $10/cow. The total hay waste on your farm may vary from the trial data summaries provided, but you can see the trend that investing in feeders that reduce hay waste can save money in the long run, if the feeders have similar life spans.

– - Easily portable hay feeders, such as the open rings, cradle, and trailer feeders are much simpler to move around the pasture, and may even reduce labor and fuel because they contain multiple bales. They also prevent nutrient build up, and reduce damage to permanent pastures, because they can be used over a larger area of the pasture. Depending on the design, they can also be significantly less efficient than other options, because more hay falls to the ground. You must evaluate the tradeoff between convenience, nutrient distribution, and pasture productivity with the amount of hay waste associated with the feeder design you select to use. I saw a wide range of designs and construction quality on display at the Sunbelt Ag Expo. I think the old saying of, “You Get What You Pay For” applies to hay feeders too. I did see a few examples of portable, multiple bale feeders that were also built to minimize the percentage of hay that reached the ground.

–

Reference Sources:

–

R. Huhnke, Round Bale Hay Storage – BAE-1716 Oklahoma State University

–

D. Lalman & K. Horton, Hay Feeder Design Effect on Hay Waste – ANSI-9413 – 2023. Oklahoma State University

–

D. Buskirk, Hay Feeder Design Can Spare Nutrients and Lower Costs – Michigan State University Extension

–

D.M. Ball, G.D. Lacefield, V.G. Allen, C.S. Hoveland, & J.H. Bouton. Forage-Livestock Quotes and Concepts. Special publication of the Oregon Forage Seed Commission, Salem, Oregon. 2014.

- 2025 Weather Summary and 2026 1st Quarter Outlook - January 16, 2026

- 2025 Average Farmland Rental Rates, Lease Agreements, and Worker Wages Summary - January 16, 2026

- Friday Features:1954 How to Dial Your Phone - January 16, 2026