by Abbey Smith | Mar 22, 2024

The 2024 Citrus Health Forum was held on February 22, at the North Florida Research & Education Center (NFREC) in Quincy, Florida. There were six educational presentations and a tradeshow with 10 booths. Growers also had the opportunity to earn Florida and Georgia...

by Hardeep Singh | Mar 1, 2024

Are you a farmer, crop consultant or industry professional passionate about sustainable agriculture and eager to showcase your skills in cotton production? Then the Florida Stakeholder Engagement Program (STEP) Cotton Competition, sponsored by the University of...

by Hardeep Singh | Dec 8, 2023

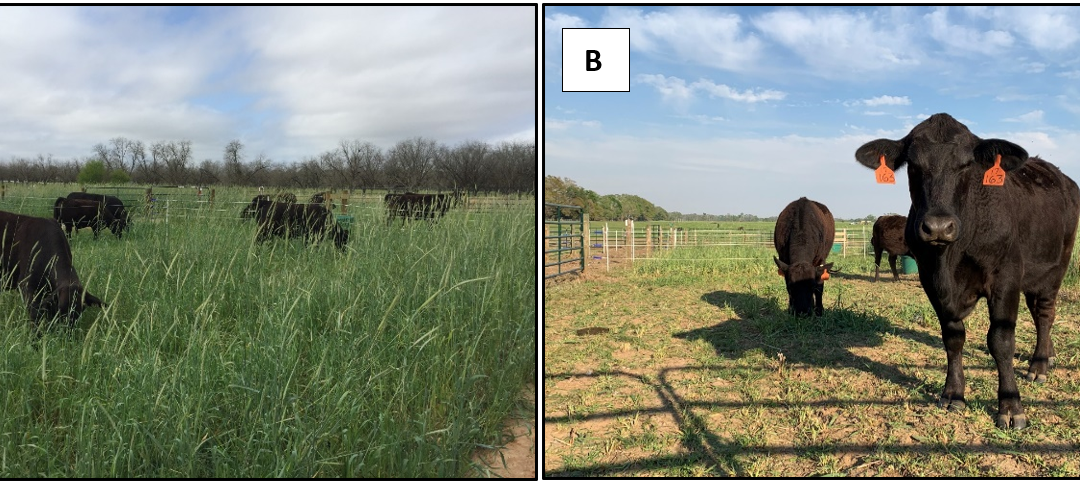

Liming, or the application of agricultural lime to soil, is a practice aimed at adjusting soil acidity levels. In North Florida, where acidic soils are common, this becomes an integral part of successful crop management. Many crops and forages perform better at a soil...

by Ethan Carter | Mar 10, 2023

The 2023 Panhandle Row Crop Short Course was held Thursday, March 2. The event had record breaking attendance going back at least a decade, with 160 people turning out. Extension Specialists from Florida and Georgia spoke to row crops farmers regarding key production...

by Cheryl Mackowiak | Dec 9, 2022

Eeusha Nafi, Sudeep Sidhu, Ted Stansly, Ian Small, Sheeja George, David Wright, Cheryl Mackowiak, UF/IFAS North Florida Research and Education Center Libbie Johnson and Ethan Carter discussed cotton nitrogen (N) rate research in the article: May Update on the Cotton...