Brand new tractor mounted sprayer in Washington County. Freshly calibrated and ready to tackle this season’s crop of weeds. Credit: Mark Mauldin, UF/IFAS

I get the pleasure of working with good people from all aspects of the agricultural industry. Each group has their own inherent set of characteristics. Unfortunately, when it comes to applying pesticides (herbicides for today’s purposes) attention to detail is not one of the characteristics I can frequently associate with “pasture people”. Far more so than with their row-crop oriented brethren, pasture folks seem oriented towards the “spray-and-pray” approach. We can do better than that. Herbicides are too expensive, and weeds too costly to do anything less than our absolute best to deliver them as effectively as possible.

Equipment

Effective application of herbicides begins with using correctly calibrated spray equipment. Regardless of whether you are applying herbicides with a traditional boom sprayer, a boomless sprayer, or a hand-held spray gun, you still need an accurate measurement of how many gallons of spray solution you are apllying. The calibration process quantifies how many gallons per acre (GPA) your spray rig applies. Tank size divided by GPA = number of acres your spray tank can cover. Given the fact that herbicide rates are generally expressed as a specific volume (oz, pts, qts,) per acre, you must know how many acres your spray tank can cover before you can determine how much chemical to add to the tank.

As previously stated, the process quantifies GPA applied. This gives the operator 1) the information needed to accurately mix herbicide to deliver the intended rate or 2) the opportunity to adjust how the equipment is operated to alter the GPA. Alterations generally relate to ground speed, pump pressure, or spray nozzle selection.

Note: Most tractor mounted pasture spray equipment typically apply between 15 and 25 GPA. This is a bit higher than typically seen in row crop settings, largely because pastures are not as smooth as crop fields, and we can’t comfortably drive as fast. This range is sufficient for most pasture products, however there are specific products and situations that call for higher spray volumes. Consult product labels, adjust (usually ground speed), and recalibrate as needed to optimize product performance.

Spray equipment should be calibrated any time there is an equipment change (sprayer is on a different tractor, ground speed is changed, new pump, new spray tips, etc.) and every few years, even if nothing obvious has changed, as insurance against over or under applying pesticides. The sprayer calibration process is relatively simple. There are links below to publications detailing how to calibrate each type of sprayer. If you would like assistance calibrating your sprayer don’t hesitate to contact your county’s UF/IFAS Agricultural Extension Agent.

Calibrating a Boom Sprayer – University of Florida

Calibrating a Boomless Sprayer – The Noble Research Institute

Tips of Calibrating Hand-Held Sprayer – University of Nebraska

If you are using a boom sprayer, part of the calibration process should be a nozzle performance test. The purpose of the test is to ensure that each nozzle is functioning correctly, and that nozzle output is uniform across the boom. The performance test should be completed at least once a year. The test can identify nozzles with clogged screens (before the issue is readily visible) and/or tips that are wearing and allowing excess flow. If you have not done a nozzle performance test recently, I would encourage you to do so before you spray this spring/summer.

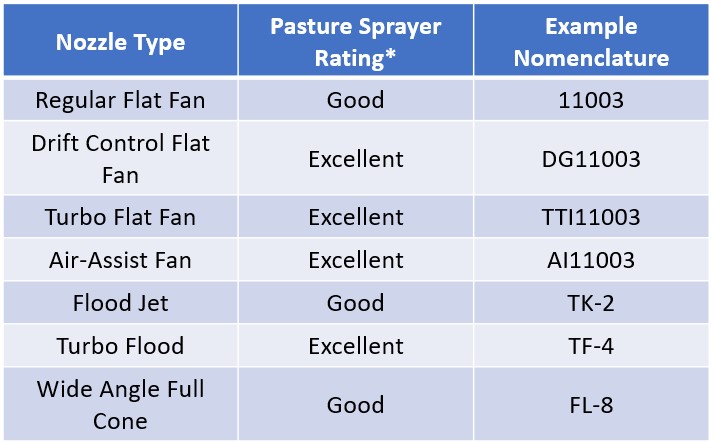

While you’ve got the sprayer out for the nozzle test, take a few minutes, and check to see what kind of spray tips you are using. There are far more options than there used to be. Many of which are excellent at delivering systemic herbicides (mostly what we spray in pastures) while greatly reducing the likelihood of drift compared to a traditional flat fan tip. Spray tips are easy to change, and an upgrade may be in order, especially if the results of the performance test come back less than ideal.

* Based on using Post-Emerge, Systemic herbicides. Source: Sprayer Nozzle Selection

–

Whether you choose to upgrade tips or not, please take the time to identify what tips you are using and be sure that they are appropriate for the rest of your setup. Each specific type of tip has a recommended spacing on the boom (generally 20 inches), spray height, and range of operating pressure. Using tips outside of their recommended parameters can seriously reduce the overall effectiveness of your spray rig.

Note: Tips generally have a wide range of operating pressures, however the size of the spray droplets produced is greatly impacted by pressure. Higher pressures yield smaller droplets which are more likely to drift. Be sure to pair tips and operating pressure so that Coarse or Very Coarse (the most appropriate size for systemic, post emergence herbicides) droplets are produced. All the operational parameters and droplet size information is available for all spray tips, it just takes some time to look it up or a call to your county’s UF/IFAS Agricultural Extension Agent.

Recommended droplet size classification by pesticide type. Source: Managing Pesticide Drift

Spray Nozzle Selection – University of Georgia

–

Product & Rate

After the equipment is in good working order, it is time to focus on the more popular aspects of weed management, herbicide product and rate selection. The ability to select the most appropriate product(s) and rates is based largely on correct weed identification and a good understanding of the herbicide tolerances of the desired forage. The process is so case specific, for now let it suffice to say, “don’t guess”, consult with someone with expertise and experience and get it right.

Weed Management in Pasture & Rangeland 2023 – University of Florida

To facilitate your discussions or research on your specific situation, I will offer two additional points to ponder which may save you a few dollars. 1) Taking the time to understand product active ingredients (and not just brand names) will make you better able to shop around to find the active ingredient you need at the best possible price. Many active ingredients (AI) are available in multiple products. As you compare products be sure you take different formulations and use rates into account when determining the best value. Always consult product labels, just because products have the same AI does not mean their labels are the same. 2) Don’t forget about tank mixes. Sometimes it takes more than one product to kill the problem weeds. Sometimes combining products allows for effective weed control at lower use rates or with cheaper chemistries.

–

Adjuvants

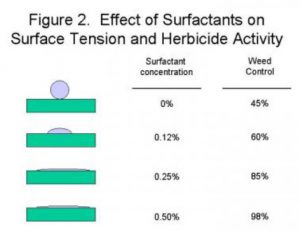

“Surfactants reduce the surface tension of spray droplets, increasing spray retention and allowing the spray droplets to spread over a larger area (Figure 2)”

Source: Role of spray adjuvants with postemergence herbicides

A thorough discussion of adjuvants (products added to the spray solution to improve pesticide efficacy) could be an article of its own. Put briefly for pasture purposes – know what kind of adjuvant works best with your product of choice and use it. The default setting for pasture products is a non-ionic surfactant (NIS) that is at least 80% active ingredient (80/20 NIS) used at 0.25% – 0.5% by volume (1-2qt per 100gallons of spray mixture). That said there are products and situations were methylated seed oil (MSO) or crop oil concentrate (COC) would be preferred over NIS. Be sure to consult product labels and use the recommended adjuvant.

It may also be worthwhile to have the water source from which you typically fill spray tanks analyzed for pH and hardness. Depending on the results of the analysis you may consider using a water conditioning agent in addition to a surfactant or oil.

The Role of Spray Adjuvants with Post Emergent Herbicides – Iowa State University

Spray Adjuvants – Penn State University

Why are Adjuvants Important and What is the Difference Between Adjuvants? – Texas A&M University

Spray water droplets on perennial peanut leaves. The spray solution contained no surfactant or other adjuvant. Note how the droplets are not spreading over the leaves. Credit: Mark Mauldin, UF/IFAS

–

Timing

After all the particulars relating to your equipment, product, rate, and adjuvants have been sorted out there is one more key factor to consider – application timing.

Spray early in the growing season. We take the time and spend the money to control weeds in pastures because they can compete with our desired forages and limit their productivity. If you wait until mid or late summer to control weeds, they have already robbed you of forage productivity for several months. Young/newly emerged weeds are much easier (and generally cheaper) to kill than their more mature counterparts. Furthermore, by waiting until late in the season there is a much higher likelihood that problem weeds have made seed. The seed, even on plants that eventually get sprayed, will lead to more weeds to deal with next year. While there are some exceptions to this rule, applications made earlier in the growing season generally give you the most bang for your buck.

Spray before the infestation gets out of hand. Diligent scouting followed by timely action can save quite a bit of money simply by allowing the issue to be handled via spot spraying before a broadcast application to the entire pasture/area is necessary. Compared to broadcast spraying, spot applications require less chemical, less time, and less equipment expense. However, spot treatments are only viable if the situation is addressed while the infestation is still confined to a manageable area.

Spray when the weeds are receptive. The systemic herbicides we typically use for post emergent pasture weed control need to be absorbed and circulated through an actively growing plant to be effective. Don’t waist your time and money spraying weeds that are stressed by drought or cold. Happy weeds are easier to kill.

Dogfennel (on the left) is much easier to control when sprayed early in the season. Get to them quickly, they are growing rapidly right now. Blackberries (on the right) are most effectively controlled with an early fall herbicide application. Credit: Mark Mauldin, UF/IFAS

–

I have made a lot of comments/recommendations, and I’ve tried very hard to keep them all general and broadly applicable. Every situation is different and needs to be evaluated as such. My main goal here was to prompt you to think about the details and how you could do a better job managing weeds on your operation. Please explore the plethora of links I’ve included for more information. Beyond that don’t hesitate to contact me directly (850-638-6180 or mdm83@ufl.edu) or reach out to your local UF/IFAS Agricultural Extension Agent to discuss anything included here in terms more specific to your situation.

Always remember to read and follow herbicide labels. Label statements always supersede any generic recommendations made in this or any other article.