by Ian Small | Jan 31, 2025

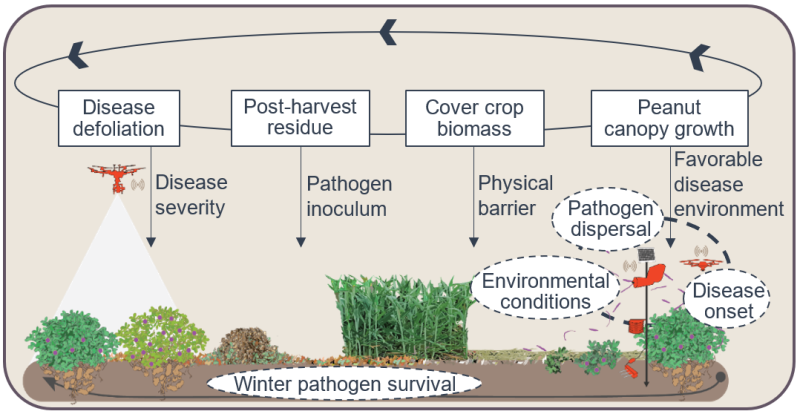

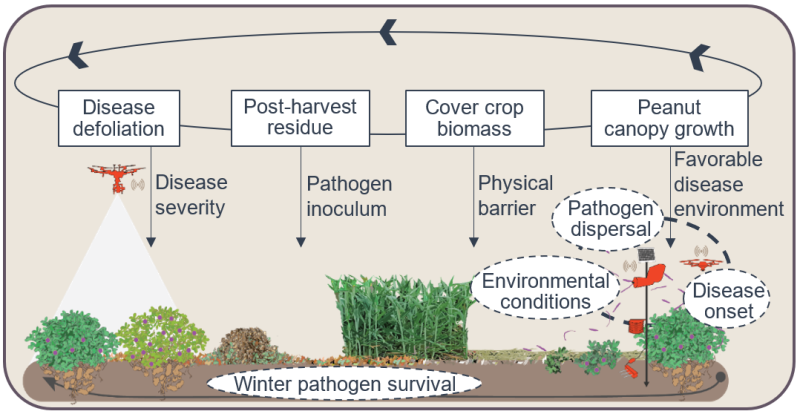

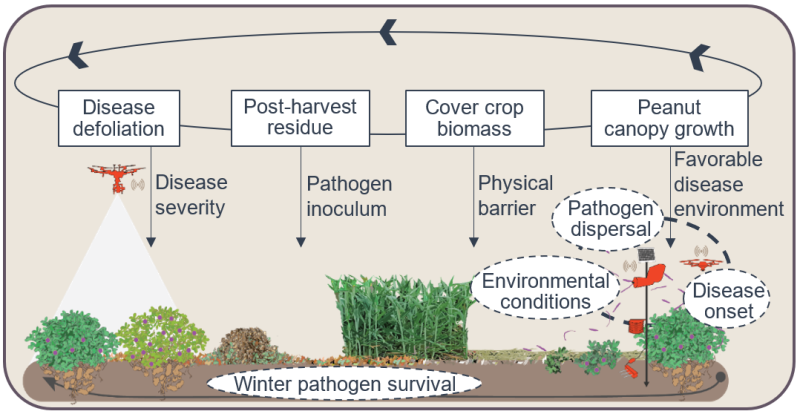

Rebecca Barocco and Ian Small, North Florida Research and Education Center-Quincy Peanut early leaf spot, late leaf spot, and stem rot (a.k.a white mold) are economically important fungal diseases that survive within fields between seasons and can cause significant...

by Ian Small | Jul 16, 2024

Ian Small, Tre Easterly, Valerie Stansly, and Sheeja George As agriculture increasingly integrates advanced technology, the gap in skills needed to support and innovate within the industry is widening. To address this challenge, a United States Department of...

by Ian Small | Jul 30, 2021

Ian Small, UF/IFAS Crop Pathology Specialist, Bob Kemerait, UGA Crop Pathology Specialist, and Matthew Burger,UF/IFAS Plant Pathology Graduate Student As most cotton growers in the Southeast approach mid-season, now is the time to be scouting for foliar diseases that...

by Ian Small | Aug 21, 2020

Ian Small, De Broughton, Fanny Iriarte, Nicholas Dufault, Keith Wynn, Jay Capasso, and David Wright, UF/IFAS Peanut Team – In recent weeks, peanut growers throughout North Florida have observed an increase in the occurrence of soil borne, pod rot diseases. In...

by Ian Small | Mar 6, 2020

Ian Small, UF/IFAS North Florida Research and Education Center (NFREC), Dan Anco, Clemson University, Department of Plant and Environmental Sciences, Kelly O’Brian, NFREC, Santosh Sanjel, NFREC, Nick Dufault, UF/IFAS Department of Plant Pathology, and David...