Figure 1. Field experiment showing a paladin chloropicrin mixture used in combination with totally impermeable film. In the foreground from the left: untreated VIF, Untreated TIF, Paladin:Pic 20 gallons per acre, Paladin:Pic 30 gallons per acre. Standard use rate for Paladin:Pic with VIF is 50-60 gallons per acre. Photo by Josh Freeman

Plastic mulch technology has come a long way in the last 15 years and has made another exponential jump in the last 5 years. Traditionally plastic films used in plasticulture production systems were simple, single layer low density polyethylene films. These are reasonably priced and for the production systems they were and are still used in, they suited the purpose. Historically speaking, they were used in combination with methyl bromide for soil fumigation purposes. Methyl bromide is a fast acting fumigant that rapidly spreads throughout the soil, and was very effective in controlling soil borne diseases and weeds. There was no reason to attempt to keep the fumigant in the soil because it acted so quickly. However, it was discovered that methyl bromide was an ozone depleting substance and a global effort was undertaken to eliminate the use of ozone depleting substances. Methyl bromide use was phased out completely by 2005, and was only used under critical use exemptions, which are now nearly completely gone in the U.S.

The phase out of methyl bromide spurred on the development of tools that could squeeze more efficacy out of annually declining use rates. Out of this period came virtually impermeable film (VIF). VIF was different than standard film because it contained a nylon polymer sandwiched within the layers of standard plastic. This polymer made the film less permeable to fumigants. Less permeability meant that fumigant was kept in the ground longer and thereby exposed weeds and pests to fumigant vapor for a longer period of time, even when less fumigant was applied. This allowed producers to maintain pest control efficacy with less fumigant, which saved money. Methyl bromide use is now gone for pre-plant fumigation in Florida, and growers are left with other options such as Telone, chloropicrin, Vapam, K-Pam, Paladin, and now Dominus.

Most who have used methyl bromide and transitioned to other fumigants have learned that they are not as effective or as user friendly as methyl bromide. In 2007 new plasticulture film was introduced and was coined totally impermeable film (TIF). TIF is different than VIF because it contains a different barrier polymer, ethylene vinyl alcohol (EVOH). EVOH is much less permeable to gasses than the nylon polymer used in VIF. It was thought that by using an even less permeable film, less fumigant could be used with TIF and pest control efficacy would be improved with available fumigants.

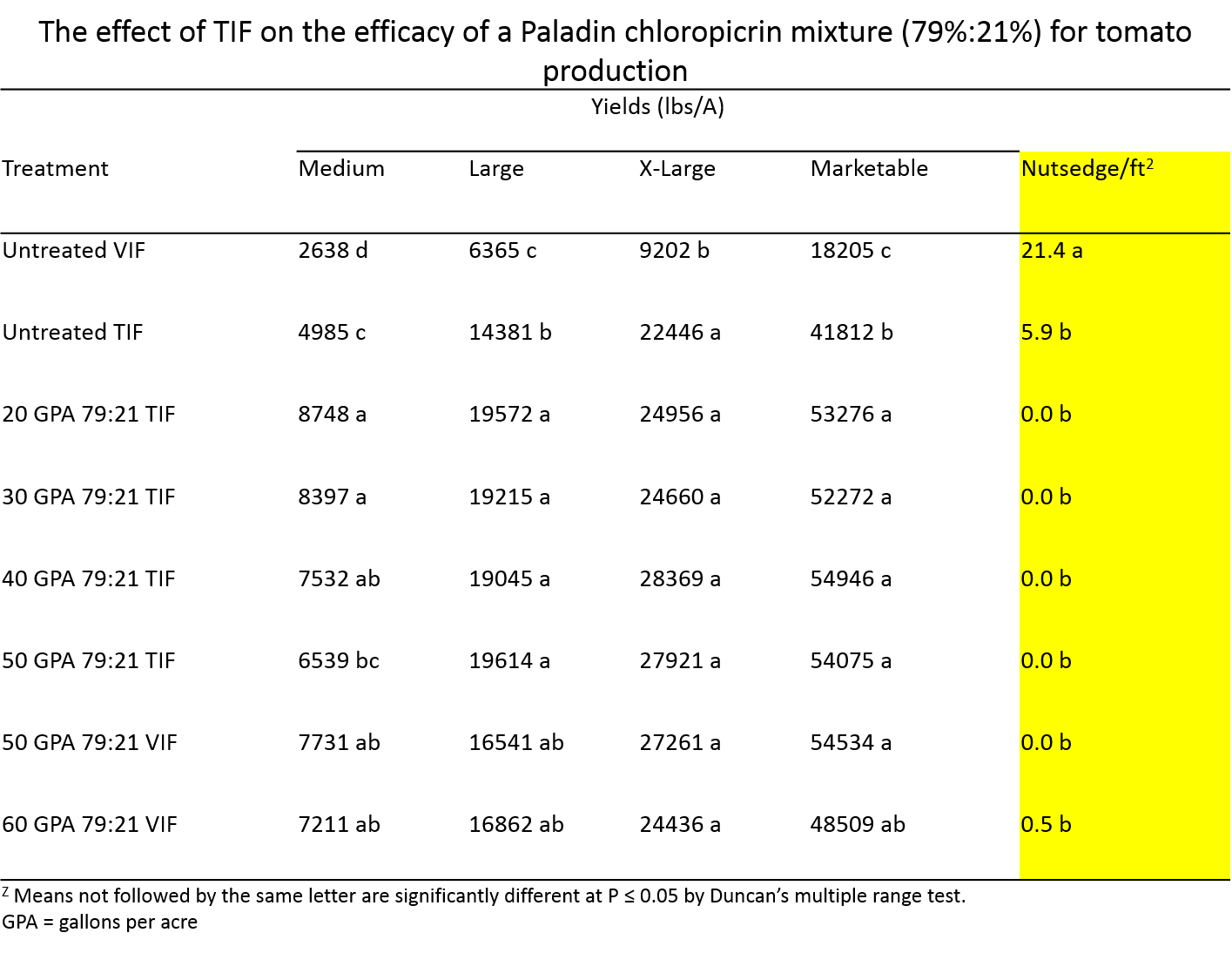

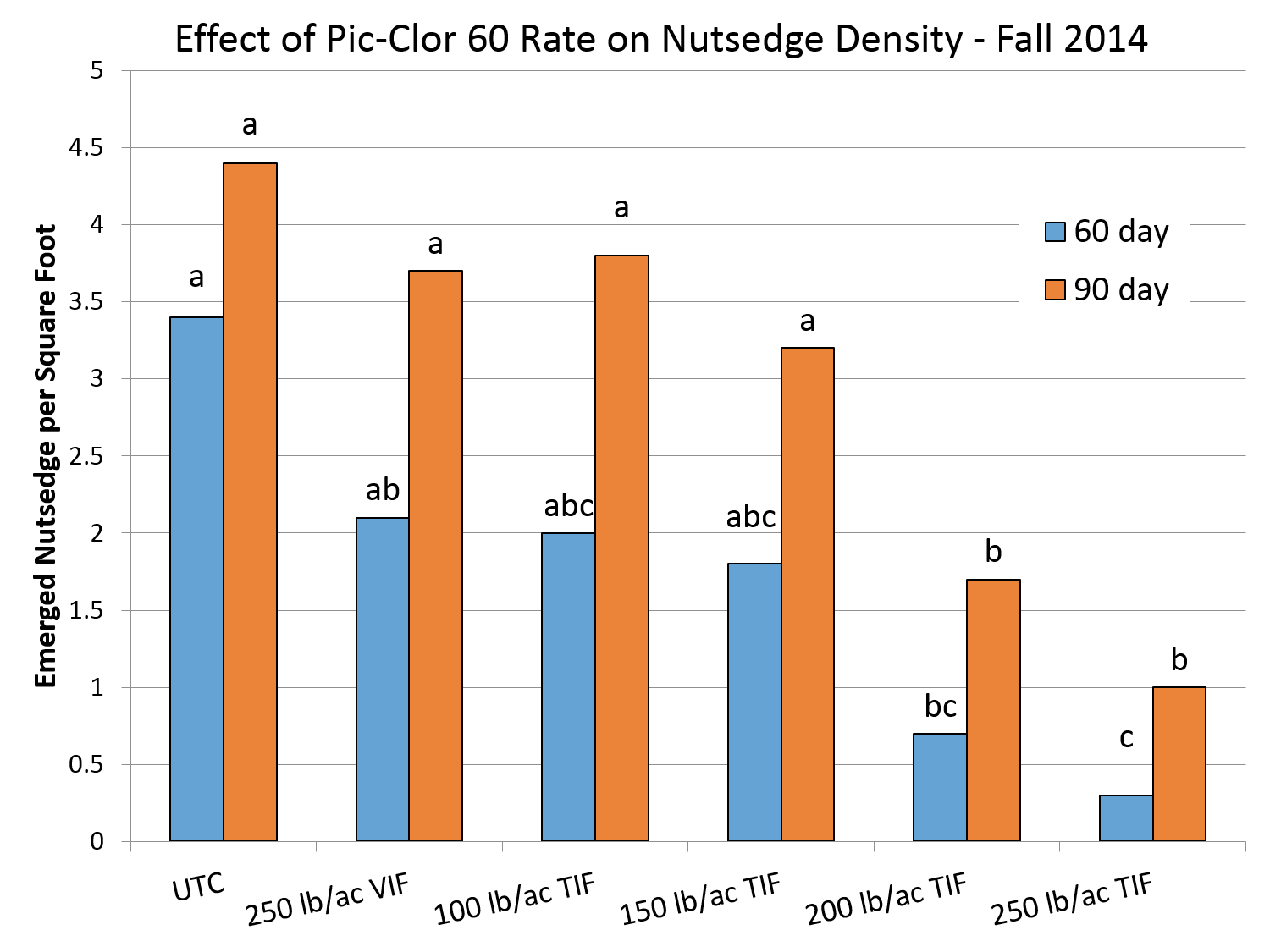

Research has demonstrated that this is in fact true, with many fumigants use rate can be reduced by 20-30% while maintaining efficacy. Tables 1 and 2 show the results from experiments investigating reduced fumigant use rates combined with TIF. The other benefit of TIF use is reduced input costs. Economic analysis shows that with Pic-Clor 60 and Paladin, a 20% reduction in use rate under TIF can save $30-60 per acre, respectively.

Though TIF mulch can provide substantial benefit there are also implications for its use. Because it retains fumigants so effectively, it has the potential to extend plant back periods, especially in the spring when cool wet conditions are common. Like any new technology there will be hurdles in adoption, but TIF warrants consideration by producers utilizing fumigants.

For more information please see the following publications:

Reduced Rates of Dimethyl Disulfide In Combination With Totally Impermeable Film Mulch

Vegetable Production Handbook: Chapter 4. Integrated Pest Management

Or contact Josh Freeman

University of Florida Vegetable Specialist

NFREC Quincy

155 Research Road

Quincy, FL 32351

Office – (850) 875-7128

joshuafr@ufl.edu

- NFREC Faculty Tribute to Arnie Forrester - February 11, 2022

- Tomato Varieties for 2022 - January 28, 2022

- Pumpkin Production in North Florida - July 30, 2021