When you hear about oyster farming, you typically hear the word “seed” and how it is highly important to the future of the farm. While it might not be a typical seed that produces agricultural crops like corn, this seed is a living, breathing (albeit in the water) organism that produces a beautiful, cupped oyster. Depending on market size demand and requirements, it could take anywhere from 8 to 24 months to reach “shucking ready” size. Let’s take a dive into the timeline of an oyster, from seed to shuck.

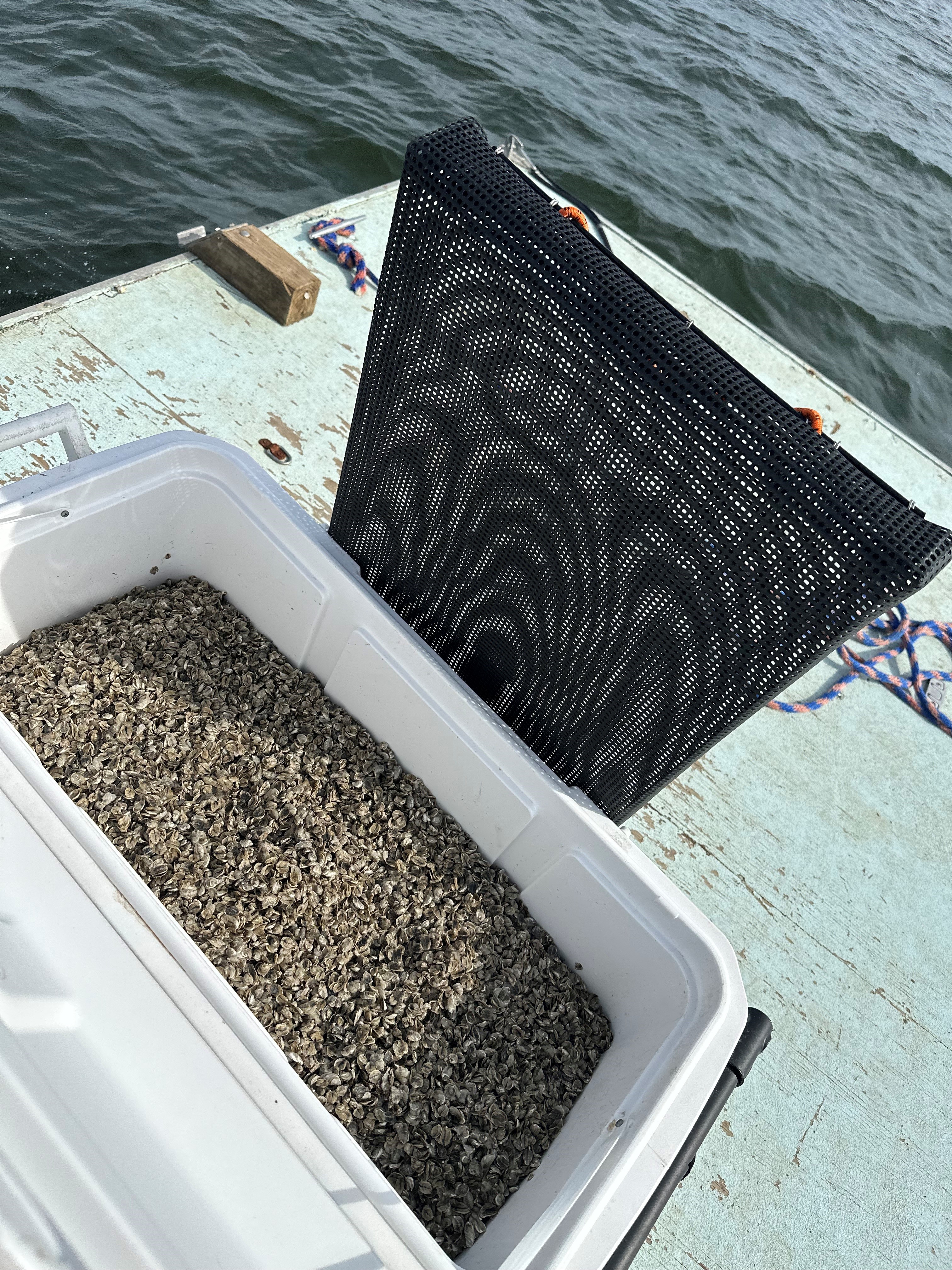

Oyster farmers typically buy seed from an oyster nursery or hatchery, where they carefully spawn male and female oysters together in individual spawning chambers. Depending on the farmer’s needs, they can produce either diploid or triploid oyster larvae (more on triploids next week). These larvae are free-swimming for the first 2-3 weeks of their life until they develop into pediveligers (Oyster 101). Hatcheries will, for lack of better terms, mix the pediveligers with very tiny grains of ground-up oyster shells. These pediveligers will then attach to a single grain and begin to form into a “seed” oyster. Seed costs range and vary from year to year, and this cost is usually one of the biggest financial purchases oyster farmers can make. Seed is sold by size, starting at 6 millimeters (typically called size R6), and by increments of 1,000. Hatcheries and nurseries are located all along the Gulf Coast, but Florida law requires seed put in the Gulf of Mexico waters and estuaries must come from Gulf of Mexico hatcheries, and the same rules apply to Atlantic waters.

Once purchased, these seed oysters make it to their homes in beautiful nutrient-rich waters and grow at a steady rate, and can reach an overall size of 2 inches in 4 to 9 months. During those months, the seed are filtering gallons of water per oyster per day, helping sequester carbon in their shells and consuming large amounts of plankton and algae that could contribute to the eutrophication of the bays. Oyster farmers will check on the seed almost weekly, changing bag mesh sizes and sorting the seed by size. Farmers will also take this opportunity to check for any oyster predators and swiftly evict them from their all-you-can-eat buffet. Sorting is done by using a “tumbler” that has a long drum with holes of varying sizes. This tumbler also helps clean the oyster and chip away at the lip of an oyster shell, causing the oyster to grow deeper and create a beautiful cup.

Farmed oysters do not have a size limit, but most farmers stick to a 2.5 to 3-inch size oyster. These oysters have filtered over 7,000 gallons of estuary water individually and sequestered a very generous amount of carbon, in the form of calcium carbonite (more here), in their shells in their first year of life. Once deemed ready for harvest, farmers will pull them out of the water and get them quickly in the fridge, following strict biosecurity guidelines and regulations to provide a safe product year-round.

And there you have it, from seed to shuck. With the holidays coming up, and seafood sometimes being a part of the holiday plans, reach out to the local oyster farmers in your area to reserve a dozen or two for your favorite uncle. You can also wow the crowd with this very fancy mignonette recipe below!

Lemon Champagne Mignonette

Juice From 2 Local Meyer Lemons (They’re in Season!)

1 Shallot Chopped Finely

½ cup Champagne Vinegar

¼ cup Red Vinegar

1 tbsp each of Green and Pink Peppercorns

24 Local Farm Raised Oysters (For the Environment!)

1. In a bowl, add the juice of Meyer lemons and shallots. Let it marinate for 10 minutes.

2. Add champagne vinegar, red vinegar, and peppercorns to the lemons and shallots.

3. Chill for at least 30 minutes in the fridge.

4. Shuck oysters and top with freshly made mignonette. Enjoy!

- Aquaculture 101: Aquaculture in The USA - May 12, 2025

- Aquaculture 101: The History of Aquaculture - April 25, 2025

- A Northwest Florida Winter Wonderland - January 31, 2025